What are the Product Standards for Coupling Capacitors?

I. Introduction

A. Definition of Coupling Capacitors

Coupling capacitors are essential components in electronic circuits, primarily used to connect two circuits while blocking direct current (DC) and allowing alternating current (AC) signals to pass. They play a crucial role in various applications, including audio equipment, radio frequency circuits, and signal processing systems. By facilitating the transfer of AC signals, coupling capacitors help maintain signal integrity and prevent unwanted DC levels from affecting circuit performance.

B. Importance of Product Standards

Product standards are critical in ensuring the reliability, safety, and performance of electronic components, including coupling capacitors. These standards provide guidelines for manufacturers, helping them produce components that meet specific electrical, mechanical, and safety requirements. Adhering to established standards not only enhances product quality but also fosters consumer confidence and promotes interoperability among different devices.

C. Overview of the Article

This article will explore the various product standards for coupling capacitors, including their functions, types, regulatory bodies, key standards, testing methods, industry applications, and future trends. By understanding these aspects, manufacturers and engineers can ensure that their coupling capacitors meet the necessary requirements for optimal performance.

II. Understanding Coupling Capacitors

A. Function and Purpose

1. Signal Coupling

The primary function of coupling capacitors is to couple AC signals between different stages of a circuit. By allowing AC signals to pass while blocking DC, these capacitors help maintain the desired signal levels and prevent distortion. This is particularly important in audio and radio frequency applications, where signal integrity is paramount.

2. DC Blocking

Coupling capacitors also serve as DC blockers, preventing unwanted DC voltage from affecting downstream components. This is crucial in circuits where DC levels can cause biasing issues or damage sensitive components. By isolating different circuit sections, coupling capacitors help ensure stable operation and protect against signal degradation.

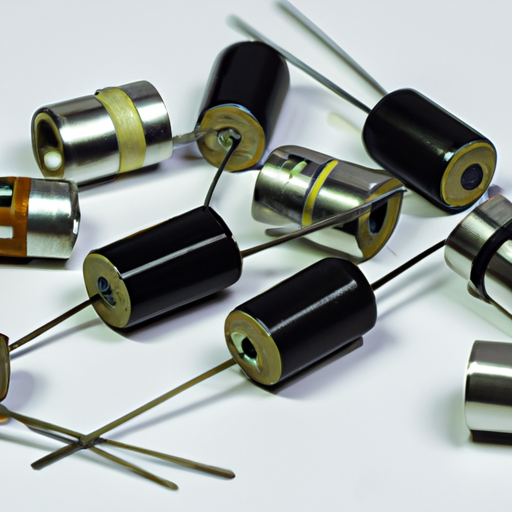

B. Types of Coupling Capacitors

There are several types of coupling capacitors, each with unique characteristics and applications:

1. Ceramic Capacitors

Ceramic capacitors are widely used for coupling applications due to their small size, low cost, and stable electrical properties. They are available in various capacitance values and voltage ratings, making them suitable for a range of applications.

2. Film Capacitors

Film capacitors offer excellent stability and low loss, making them ideal for high-frequency applications. They are available in various dielectric materials, such as polyester, polypropylene, and polystyrene, each providing different performance characteristics.

3. Electrolytic Capacitors

Electrolytic capacitors are typically used in applications requiring high capacitance values. While they are not commonly used for coupling due to their polarity, they can be employed in specific applications where DC blocking is not a concern.

4. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance-to-volume ratio and stability. They are often used in compact electronic devices where space is limited, but they require careful handling due to their sensitivity to voltage and temperature variations.

III. Regulatory Bodies and Standards Organizations

Several organizations are responsible for establishing and maintaining product standards for coupling capacitors:

A. International Electrotechnical Commission (IEC)

The IEC develops international standards for electrical and electronic devices, including capacitors. Their standards ensure compatibility and safety across different countries and regions.

B. Institute of Electrical and Electronics Engineers (IEEE)

IEEE is a leading organization in the development of standards for electrical and electronic systems. Their standards cover various aspects of capacitor performance, including testing methods and application guidelines.

C. American National Standards Institute (ANSI)

ANSI oversees the development of voluntary consensus standards for products and services in the United States. Their standards help ensure that coupling capacitors meet specific performance and safety criteria.

D. Underwriters Laboratories (UL)

UL is a global safety certification organization that tests and certifies products for safety and performance. Their standards for capacitors focus on electrical safety, fire resistance, and environmental considerations.

E. Other Relevant Organizations

Other organizations, such as the European Committee for Electrotechnical Standardization (CENELEC) and the Japan Electronics and Information Technology Industries Association (JEITA), also contribute to the development of standards for coupling capacitors.

IV. Key Product Standards for Coupling Capacitors

A. Electrical Characteristics

1. Capacitance Tolerance

Capacitance tolerance specifies the allowable deviation from the nominal capacitance value. It is crucial for ensuring that coupling capacitors perform as expected in a circuit. Common tolerances range from ±5% to ±20%, depending on the capacitor type and application.

2. Voltage Rating

The voltage rating indicates the maximum voltage a capacitor can withstand without failure. It is essential to select coupling capacitors with appropriate voltage ratings to prevent breakdown and ensure reliable operation.

3. Temperature Coefficient

The temperature coefficient describes how capacitance changes with temperature. Capacitors with low temperature coefficients are preferred in applications where temperature variations are expected, as they maintain stable performance across a range of conditions.

4. Equivalent Series Resistance (ESR)

ESR is a critical parameter that affects the performance of coupling capacitors, particularly in high-frequency applications. Low ESR values are desirable, as they minimize power loss and improve signal integrity.

B. Mechanical and Environmental Standards

1. Size and Form Factor

The physical dimensions and form factor of coupling capacitors are essential for ensuring compatibility with circuit designs. Standards specify the allowable sizes and shapes for different capacitor types.

2. Operating Temperature Range

Coupling capacitors must operate reliably within specified temperature ranges. Standards define the minimum and maximum operating temperatures to ensure performance under various environmental conditions.

3. Humidity and Moisture Resistance

Capacitors must be resistant to humidity and moisture to prevent degradation and failure. Standards outline testing methods for assessing moisture resistance and establishing acceptable performance levels.

4. Vibration and Shock Resistance

In applications where capacitors are subjected to mechanical stress, standards specify requirements for vibration and shock resistance. This ensures that coupling capacitors can withstand harsh operating conditions without failure.

C. Safety and Compliance Standards

1. Flammability Ratings

Flammability ratings assess the fire resistance of capacitor materials. Standards require that coupling capacitors meet specific flammability criteria to minimize fire hazards in electronic devices.

2. RoHS Compliance

The Restriction of Hazardous Substances (RoHS) directive restricts the use of certain hazardous materials in electronic products. Compliance with RoHS is essential for manufacturers to ensure their products are environmentally friendly and safe for consumers.

3. REACH Compliance

REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is a European Union regulation that addresses the production and use of chemical substances. Compliance with REACH ensures that coupling capacitors do not contain harmful substances that could pose risks to human health or the environment.

V. Testing and Quality Assurance

A. Testing Methods for Coupling Capacitors

1. Capacitance Measurement

Capacitance measurement is a fundamental test to verify that a capacitor meets its specified capacitance value. Various methods, such as LCR meters and capacitance bridges, are used to perform this measurement.

2. Leakage Current Testing

Leakage current testing assesses the amount of current that flows through a capacitor when a voltage is applied. High leakage currents can indicate potential failure, making this test critical for ensuring capacitor reliability.

3. Dielectric Strength Testing

Dielectric strength testing evaluates a capacitor's ability to withstand high voltages without breakdown. This test is essential for ensuring that coupling capacitors can operate safely under specified voltage conditions.

B. Quality Assurance Processes

1. Incoming Inspection

Incoming inspection involves evaluating raw materials and components before they are used in manufacturing. This process ensures that only high-quality materials are utilized in the production of coupling capacitors.

2. In-Process Quality Control

In-process quality control involves monitoring production processes to identify and address any issues that may arise during manufacturing. This proactive approach helps maintain product quality and consistency.

3. Final Product Testing

Final product testing is conducted to verify that finished coupling capacitors meet all specified standards and requirements. This comprehensive testing ensures that only reliable and high-quality products reach the market.

VI. Industry Applications and Considerations

A. Consumer Electronics

Coupling capacitors are widely used in consumer electronics, such as smartphones, televisions, and audio equipment. Their ability to maintain signal integrity while blocking DC makes them essential for high-quality audio and video performance.

B. Automotive Applications

In automotive applications, coupling capacitors are used in various systems, including infotainment, navigation, and safety features. Their reliability and performance are critical for ensuring the proper functioning of these systems.

C. Industrial Equipment

Industrial equipment often requires robust coupling capacitors to withstand harsh operating conditions. These capacitors are used in motor drives, power supplies, and control systems, where reliability is paramount.

D. Telecommunications

In telecommunications, coupling capacitors are essential for signal processing and transmission. They help maintain signal quality in various devices, including routers, switches, and base stations.

E. Medical Devices

Medical devices require high-quality coupling capacitors to ensure accurate signal processing and patient safety. Compliance with stringent safety and performance standards is critical in this industry.

VII. Challenges and Future Trends

A. Evolving Standards and Regulations

As technology advances, product standards for coupling capacitors continue to evolve. Manufacturers must stay informed about changes in regulations and standards to ensure compliance and maintain product quality.

B. Technological Advancements in Capacitor Design

Innovations in capacitor design, such as the development of new materials and manufacturing techniques, are driving improvements in performance and reliability. These advancements will likely lead to the creation of more efficient and compact coupling capacitors.

C. Sustainability and Environmental Considerations

With increasing awareness of environmental issues, manufacturers are focusing on sustainability in capacitor production. This includes using eco-friendly materials, reducing waste, and ensuring compliance with environmental regulations.

VIII. Conclusion

A. Recap of the Importance of Standards

Product standards for coupling capacitors are essential for ensuring reliability, safety, and performance in electronic circuits. By adhering to established standards, manufacturers can produce high-quality components that meet the needs of various applications.

B. The Role of Standards in Ensuring Quality and Safety

Standards play a crucial role in maintaining quality and safety in the production of coupling capacitors. They provide guidelines for manufacturers, helping them produce components that meet specific electrical, mechanical, and safety requirements.

C. Future Outlook for Coupling Capacitors and Standards

As technology continues to evolve, the standards governing coupling capacitors will also adapt to meet new challenges and requirements. By staying informed about these changes, manufacturers can ensure that their products remain competitive and compliant in an ever-changing market.

IX. References

A. List of Standards and Guidelines

1. IEC 60384-14: Fixed capacitors for use in electronic equipment.

2. IEEE 18: Standard for the measurement of capacitance and dissipation factor of capacitors.

3. ANSI C63.4: Standard for methods of measurement of radio noise emissions from low voltage electrical and electronic equipment.

B. Recommended Reading and Resources

1. "Capacitor Handbook" by M. H. Rashid

2. "Electronic Components: A Complete Reference for Engineers and Technicians" by John L. Hennessy

3. Online resources from organizations like IEC, IEEE, and UL for the latest standards and guidelines.

This comprehensive overview of product standards for coupling capacitors highlights their importance in ensuring quality and safety in electronic applications. By understanding these standards, manufacturers and engineers can make informed decisions that enhance the performance and reliability of their products.

What are the Product Standards for Coupling Capacitors?

I. Introduction

A. Definition of Coupling Capacitors

Coupling capacitors are essential components in electronic circuits, primarily used to connect two circuits while blocking direct current (DC) and allowing alternating current (AC) signals to pass. They play a crucial role in various applications, including audio equipment, radio frequency circuits, and signal processing systems. By facilitating the transfer of AC signals, coupling capacitors help maintain signal integrity and prevent unwanted DC levels from affecting circuit performance.

B. Importance of Product Standards

Product standards are critical in ensuring the reliability, safety, and performance of electronic components, including coupling capacitors. These standards provide guidelines for manufacturers, helping them produce components that meet specific electrical, mechanical, and safety requirements. Adhering to established standards not only enhances product quality but also fosters consumer confidence and promotes interoperability among different devices.

C. Overview of the Article

This article will explore the various product standards for coupling capacitors, including their functions, types, regulatory bodies, key standards, testing methods, industry applications, and future trends. By understanding these aspects, manufacturers and engineers can ensure that their coupling capacitors meet the necessary requirements for optimal performance.

II. Understanding Coupling Capacitors

A. Function and Purpose

1. Signal Coupling

The primary function of coupling capacitors is to couple AC signals between different stages of a circuit. By allowing AC signals to pass while blocking DC, these capacitors help maintain the desired signal levels and prevent distortion. This is particularly important in audio and radio frequency applications, where signal integrity is paramount.

2. DC Blocking

Coupling capacitors also serve as DC blockers, preventing unwanted DC voltage from affecting downstream components. This is crucial in circuits where DC levels can cause biasing issues or damage sensitive components. By isolating different circuit sections, coupling capacitors help ensure stable operation and protect against signal degradation.

B. Types of Coupling Capacitors

There are several types of coupling capacitors, each with unique characteristics and applications:

1. Ceramic Capacitors

Ceramic capacitors are widely used for coupling applications due to their small size, low cost, and stable electrical properties. They are available in various capacitance values and voltage ratings, making them suitable for a range of applications.

2. Film Capacitors

Film capacitors offer excellent stability and low loss, making them ideal for high-frequency applications. They are available in various dielectric materials, such as polyester, polypropylene, and polystyrene, each providing different performance characteristics.

3. Electrolytic Capacitors

Electrolytic capacitors are typically used in applications requiring high capacitance values. While they are not commonly used for coupling due to their polarity, they can be employed in specific applications where DC blocking is not a concern.

4. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance-to-volume ratio and stability. They are often used in compact electronic devices where space is limited, but they require careful handling due to their sensitivity to voltage and temperature variations.

III. Regulatory Bodies and Standards Organizations

Several organizations are responsible for establishing and maintaining product standards for coupling capacitors:

A. International Electrotechnical Commission (IEC)

The IEC develops international standards for electrical and electronic devices, including capacitors. Their standards ensure compatibility and safety across different countries and regions.

B. Institute of Electrical and Electronics Engineers (IEEE)

IEEE is a leading organization in the development of standards for electrical and electronic systems. Their standards cover various aspects of capacitor performance, including testing methods and application guidelines.

C. American National Standards Institute (ANSI)

ANSI oversees the development of voluntary consensus standards for products and services in the United States. Their standards help ensure that coupling capacitors meet specific performance and safety criteria.

D. Underwriters Laboratories (UL)

UL is a global safety certification organization that tests and certifies products for safety and performance. Their standards for capacitors focus on electrical safety, fire resistance, and environmental considerations.

E. Other Relevant Organizations

Other organizations, such as the European Committee for Electrotechnical Standardization (CENELEC) and the Japan Electronics and Information Technology Industries Association (JEITA), also contribute to the development of standards for coupling capacitors.

IV. Key Product Standards for Coupling Capacitors

A. Electrical Characteristics

1. Capacitance Tolerance

Capacitance tolerance specifies the allowable deviation from the nominal capacitance value. It is crucial for ensuring that coupling capacitors perform as expected in a circuit. Common tolerances range from ±5% to ±20%, depending on the capacitor type and application.

2. Voltage Rating

The voltage rating indicates the maximum voltage a capacitor can withstand without failure. It is essential to select coupling capacitors with appropriate voltage ratings to prevent breakdown and ensure reliable operation.

3. Temperature Coefficient

The temperature coefficient describes how capacitance changes with temperature. Capacitors with low temperature coefficients are preferred in applications where temperature variations are expected, as they maintain stable performance across a range of conditions.

4. Equivalent Series Resistance (ESR)

ESR is a critical parameter that affects the performance of coupling capacitors, particularly in high-frequency applications. Low ESR values are desirable, as they minimize power loss and improve signal integrity.

B. Mechanical and Environmental Standards

1. Size and Form Factor

The physical dimensions and form factor of coupling capacitors are essential for ensuring compatibility with circuit designs. Standards specify the allowable sizes and shapes for different capacitor types.

2. Operating Temperature Range

Coupling capacitors must operate reliably within specified temperature ranges. Standards define the minimum and maximum operating temperatures to ensure performance under various environmental conditions.

3. Humidity and Moisture Resistance

Capacitors must be resistant to humidity and moisture to prevent degradation and failure. Standards outline testing methods for assessing moisture resistance and establishing acceptable performance levels.

4. Vibration and Shock Resistance

In applications where capacitors are subjected to mechanical stress, standards specify requirements for vibration and shock resistance. This ensures that coupling capacitors can withstand harsh operating conditions without failure.

C. Safety and Compliance Standards

1. Flammability Ratings

Flammability ratings assess the fire resistance of capacitor materials. Standards require that coupling capacitors meet specific flammability criteria to minimize fire hazards in electronic devices.

2. RoHS Compliance

The Restriction of Hazardous Substances (RoHS) directive restricts the use of certain hazardous materials in electronic products. Compliance with RoHS is essential for manufacturers to ensure their products are environmentally friendly and safe for consumers.

3. REACH Compliance

REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is a European Union regulation that addresses the production and use of chemical substances. Compliance with REACH ensures that coupling capacitors do not contain harmful substances that could pose risks to human health or the environment.

V. Testing and Quality Assurance

A. Testing Methods for Coupling Capacitors

1. Capacitance Measurement

Capacitance measurement is a fundamental test to verify that a capacitor meets its specified capacitance value. Various methods, such as LCR meters and capacitance bridges, are used to perform this measurement.

2. Leakage Current Testing

Leakage current testing assesses the amount of current that flows through a capacitor when a voltage is applied. High leakage currents can indicate potential failure, making this test critical for ensuring capacitor reliability.

3. Dielectric Strength Testing

Dielectric strength testing evaluates a capacitor's ability to withstand high voltages without breakdown. This test is essential for ensuring that coupling capacitors can operate safely under specified voltage conditions.

B. Quality Assurance Processes

1. Incoming Inspection

Incoming inspection involves evaluating raw materials and components before they are used in manufacturing. This process ensures that only high-quality materials are utilized in the production of coupling capacitors.

2. In-Process Quality Control

In-process quality control involves monitoring production processes to identify and address any issues that may arise during manufacturing. This proactive approach helps maintain product quality and consistency.

3. Final Product Testing

Final product testing is conducted to verify that finished coupling capacitors meet all specified standards and requirements. This comprehensive testing ensures that only reliable and high-quality products reach the market.

VI. Industry Applications and Considerations

A. Consumer Electronics

Coupling capacitors are widely used in consumer electronics, such as smartphones, televisions, and audio equipment. Their ability to maintain signal integrity while blocking DC makes them essential for high-quality audio and video performance.

B. Automotive Applications

In automotive applications, coupling capacitors are used in various systems, including infotainment, navigation, and safety features. Their reliability and performance are critical for ensuring the proper functioning of these systems.

C. Industrial Equipment

Industrial equipment often requires robust coupling capacitors to withstand harsh operating conditions. These capacitors are used in motor drives, power supplies, and control systems, where reliability is paramount.

D. Telecommunications

In telecommunications, coupling capacitors are essential for signal processing and transmission. They help maintain signal quality in various devices, including routers, switches, and base stations.

E. Medical Devices

Medical devices require high-quality coupling capacitors to ensure accurate signal processing and patient safety. Compliance with stringent safety and performance standards is critical in this industry.

VII. Challenges and Future Trends

A. Evolving Standards and Regulations

As technology advances, product standards for coupling capacitors continue to evolve. Manufacturers must stay informed about changes in regulations and standards to ensure compliance and maintain product quality.

B. Technological Advancements in Capacitor Design

Innovations in capacitor design, such as the development of new materials and manufacturing techniques, are driving improvements in performance and reliability. These advancements will likely lead to the creation of more efficient and compact coupling capacitors.

C. Sustainability and Environmental Considerations

With increasing awareness of environmental issues, manufacturers are focusing on sustainability in capacitor production. This includes using eco-friendly materials, reducing waste, and ensuring compliance with environmental regulations.

VIII. Conclusion

A. Recap of the Importance of Standards

Product standards for coupling capacitors are essential for ensuring reliability, safety, and performance in electronic circuits. By adhering to established standards, manufacturers can produce high-quality components that meet the needs of various applications.

B. The Role of Standards in Ensuring Quality and Safety

Standards play a crucial role in maintaining quality and safety in the production of coupling capacitors. They provide guidelines for manufacturers, helping them produce components that meet specific electrical, mechanical, and safety requirements.

C. Future Outlook for Coupling Capacitors and Standards

As technology continues to evolve, the standards governing coupling capacitors will also adapt to meet new challenges and requirements. By staying informed about these changes, manufacturers can ensure that their products remain competitive and compliant in an ever-changing market.

IX. References

A. List of Standards and Guidelines

1. IEC 60384-14: Fixed capacitors for use in electronic equipment.

2. IEEE 18: Standard for the measurement of capacitance and dissipation factor of capacitors.

3. ANSI C63.4: Standard for methods of measurement of radio noise emissions from low voltage electrical and electronic equipment.

B. Recommended Reading and Resources

1. "Capacitor Handbook" by M. H. Rashid

2. "Electronic Components: A Complete Reference for Engineers and Technicians" by John L. Hennessy

3. Online resources from organizations like IEC, IEEE, and UL for the latest standards and guidelines.

This comprehensive overview of product standards for coupling capacitors highlights their importance in ensuring quality and safety in electronic applications. By understanding these standards, manufacturers and engineers can make informed decisions that enhance the performance and reliability of their products.